Advantages of Precision Metal Stampings with Ultra Tool & Manufacturing

Advantages of Precision Metal Stampings with Ultra Tool & Manufacturing May 27, 2021

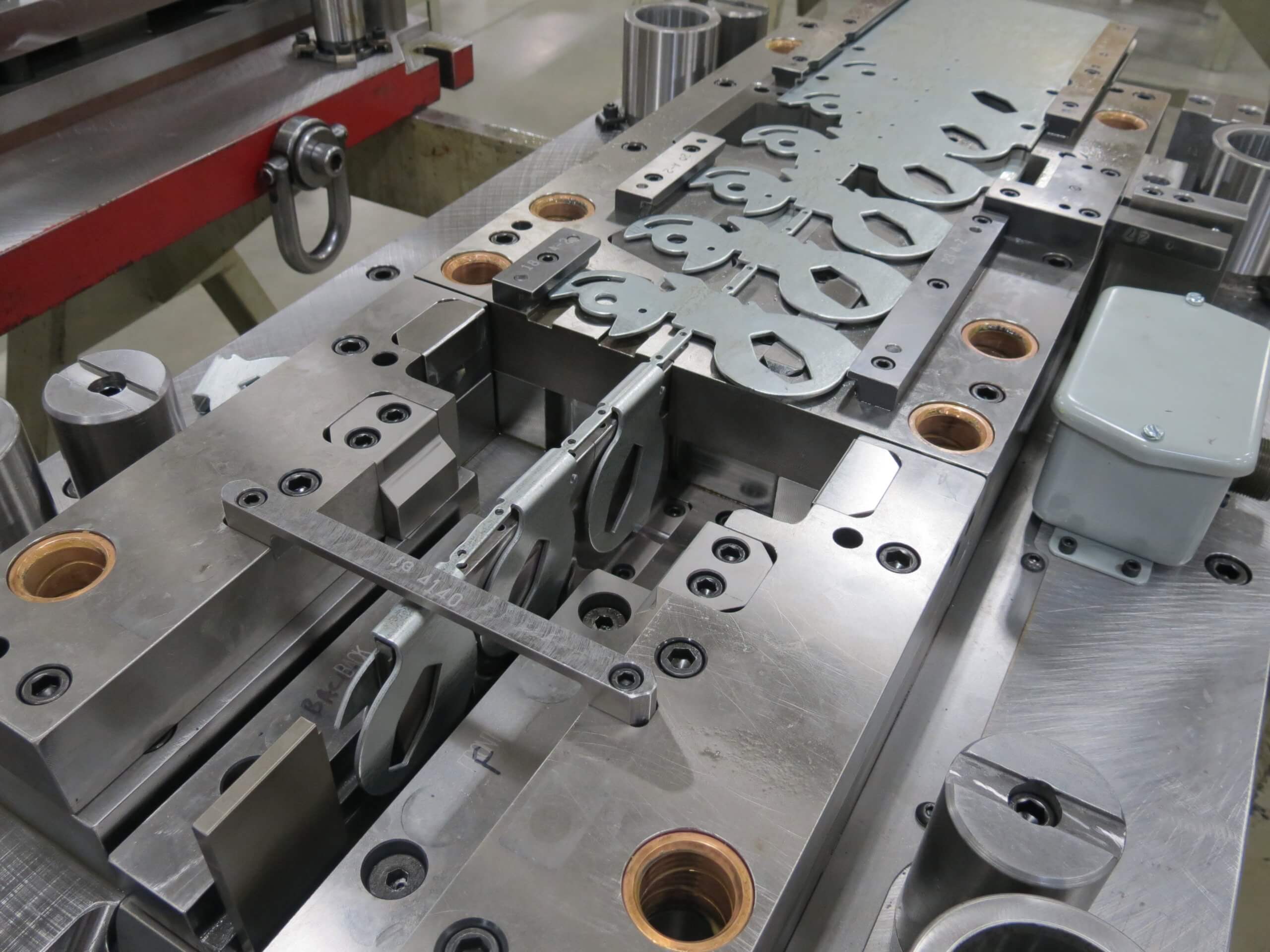

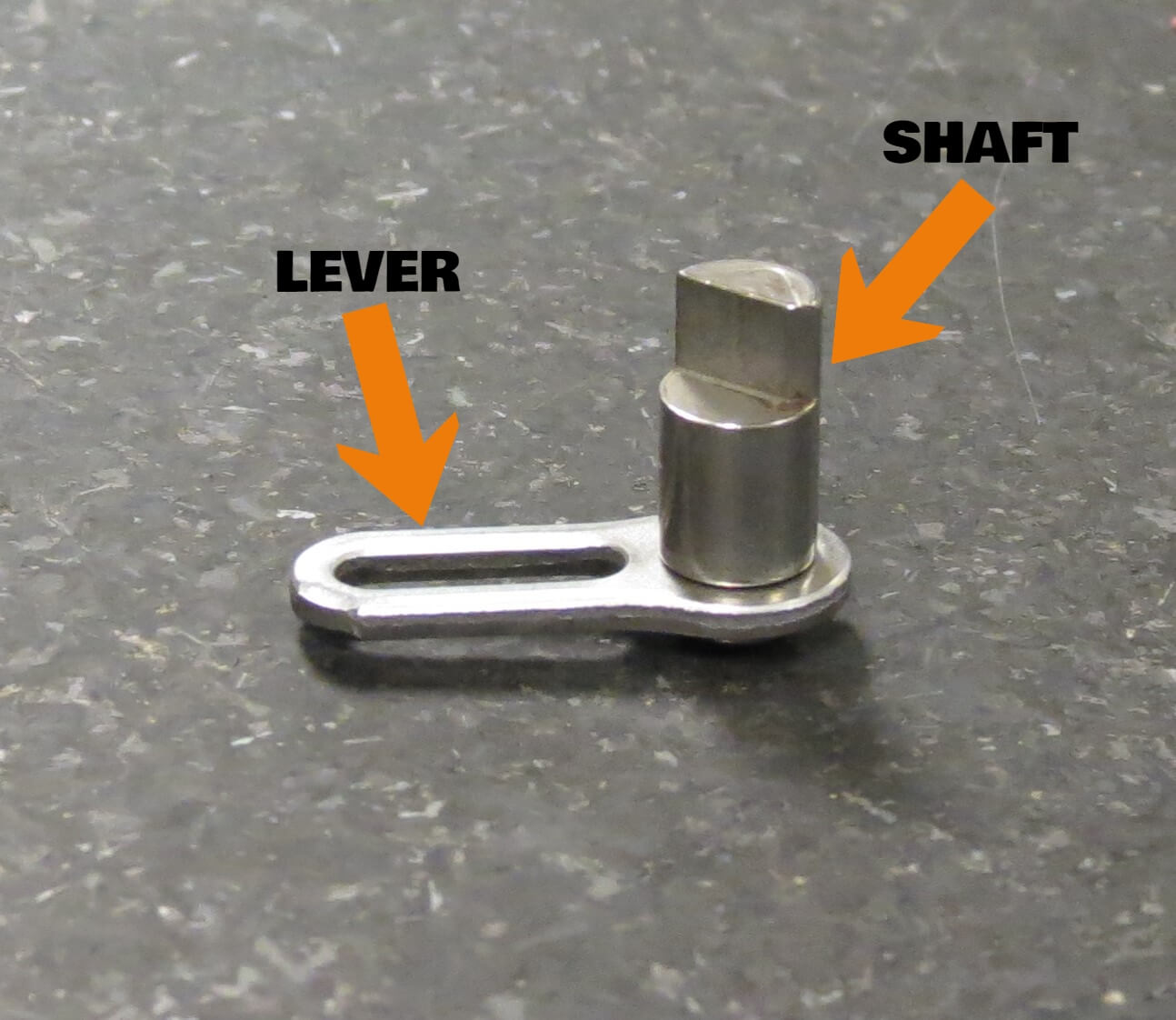

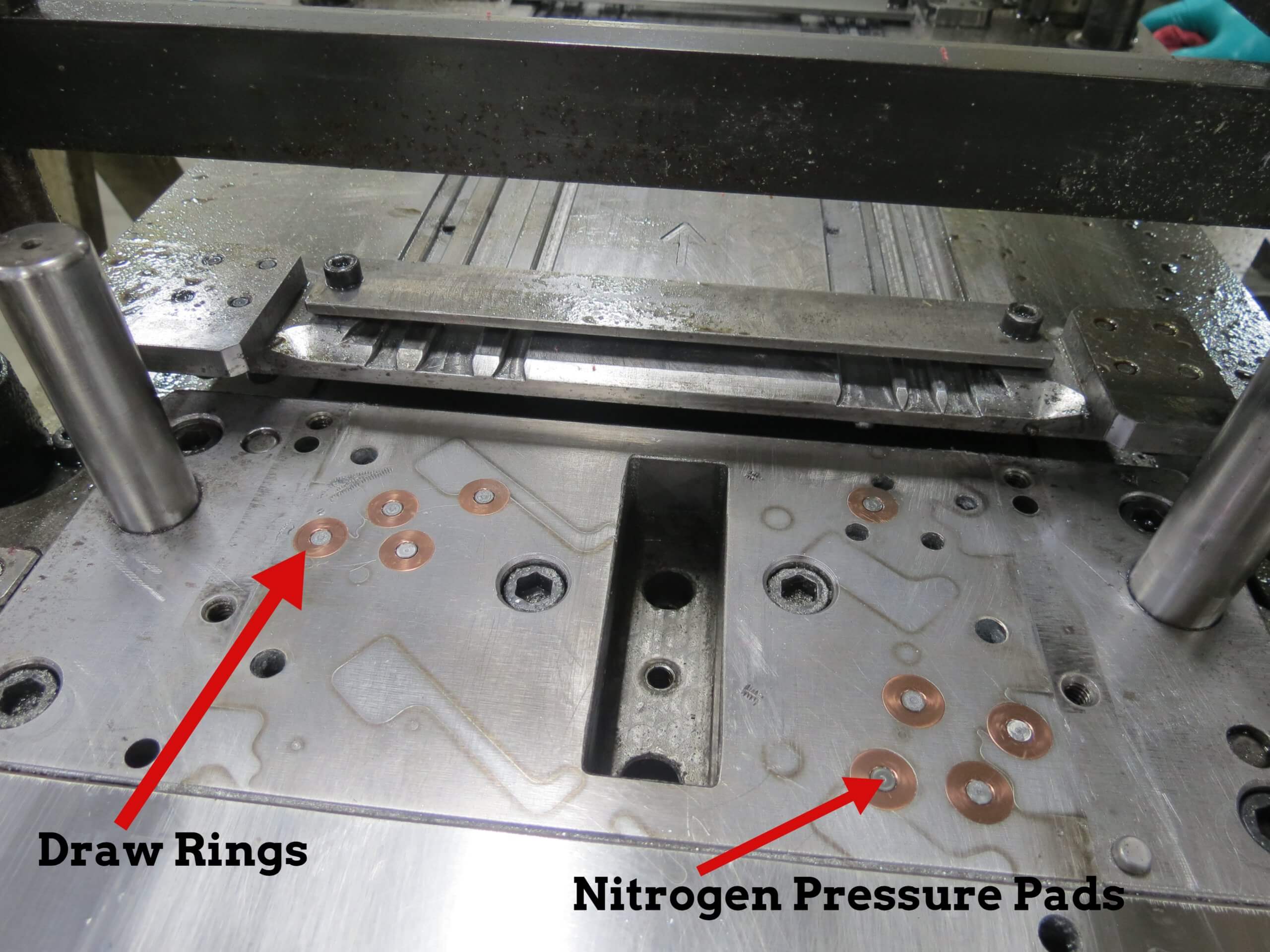

Precision metal stamping provides an efficient way to process sheet metal in coils, strips, or blanks into parts using dies and extremely accurate stampings. Learn the benefits of precision metal stamping for your high-volume production runs. If you work in the following industries, you probably rely on precision metal stampings to create the parts you […]