Comprehensive metal stamping services

We align our technical expertise and equipment to meet quality, cost, and delivery goals for stamped metal parts.

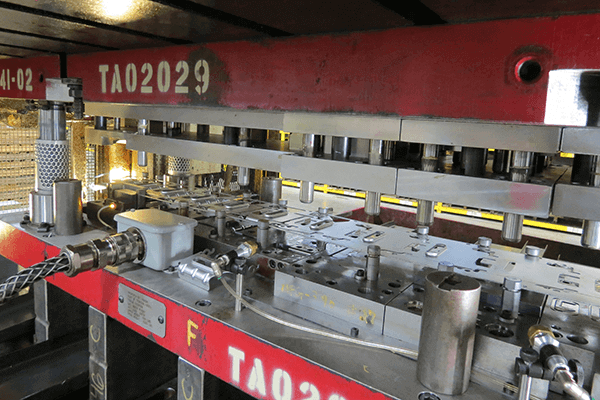

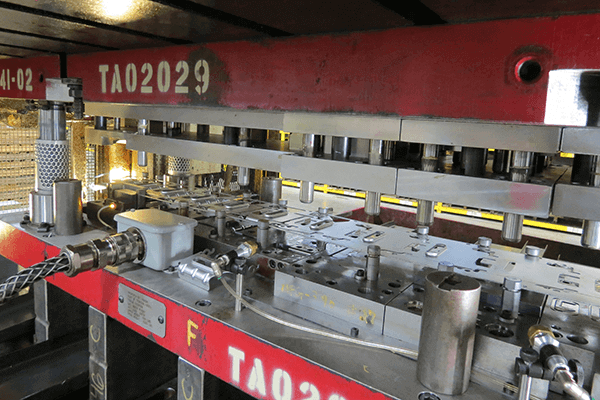

Our in-house Tool Room builds innovative stamping dies to expand our metal stamping capabilities and streamline production. A quality process is established prior to production and is followed throughout to ensure defect-free parts are delivered. Value-added operations provide a manufacturing process that is all-inclusive and hassle-free.

Metal Stamping Capabilities

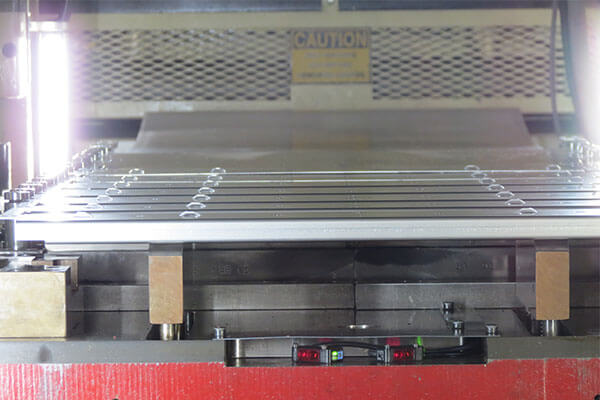

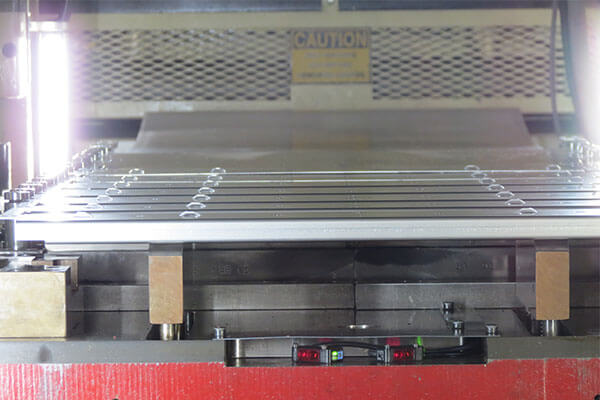

Our 13 precision metal stamping presses – 45 to 800 tons – operate with an advanced press control system that utilizes in-die sensor technology to meet low-to-high volume production needs and protect your stamping die.

Our stamping scope is wide-reaching for multiple industries from producing a 5mm part utilized in industrial automation to a 31-inch part applied to fitness equipment.

- ERP-system manages production schedules and quality inspections

- In-house tool room builds progressive stamping dies that perform multiple operations including in-die assembly and tapping

- Sensor technology protects stamping dies during production and ensures operations are functioning properly

- Greater control and flexibility of the stroke in the servo press delivers metal parts more quickly and with greater precision

- Detailed quality inspections are performed on the stamping floor and in the quality lab.

- The completion of metal parts is performed in-house with sub-assembly services, finish and line ready packaging.

- In-house die maintenance performs repairs and modifies dies within set deadlines

Our stamping services

- Bending

- Blanking

- Deep drawing

- Coining

- Curling

- Hemming

- Ironing

- Piercing

- Cutting

Metal Stamping Technology We Use

Cost-saving, sensor-controlled tooling

A progressive stamping die is a major investment for customers and we protect this asset by utilizing in-die sensor technology. Our computerized press control system connects with this in-die sensor technology to monitor and maintain metal stamping operations. This system identifies production issues before costly damages occur, allows for the stamping press to operate at maximum speed, and decreases production times. Optimizing this technology improves our ability to precisely metal stamp complex shapes and work with a wide variety of materials.

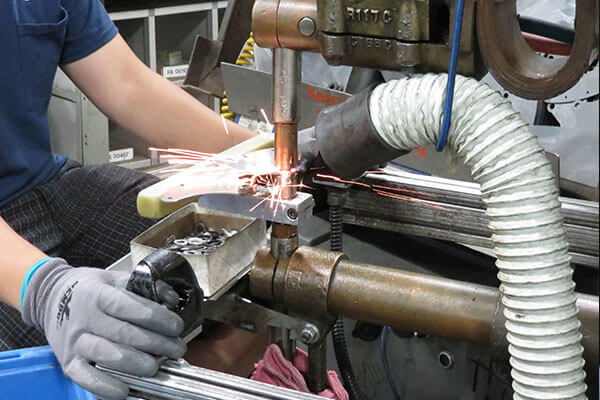

We also utilize die technology to install secondary operations into our progressive stamping dies and reduce secondary manufacturing costs. We can weld, tap holes, assemble components, and make measurements during metal stamping.

Quality

An integrated quality process helps establish a successful metal stamping environment with regular quality inspections to prevent production issues.

PPAP (Pre-production approval process)

This is completed before full production can start on a new or redesigned metal part utilizing standard and customized quality criteria. PPAP includes a Layout Inspection – which measures every dimension of a metal part with micrometers, calipers, and automated equipment.

CMM – The probe of the Coordinate Measurement Machine precisely touches multiple points on a metal part that cannot be done by the human hand.

Faro Arm – This measurement equipment has highly accurate lasers that can scan 560,000 points per second providing the ability to quickly and precisely define a metal part's layout. This accelerates the pre-production process without sacrificing quality and details. It pinpoints inaccuracies allowing for design corrections before a part moves into full production.

1st piece inspection

This quality inspection is performed every time any stamping press performs an initial run of a metal part in a pre-determined quantity. This ensures the production process is set-up correctly to complete a production order without interruptions. During metal stamping operations, the ERP-system establishes the types of quality inspections as well as the frequency and the press operator is notified at their workstation.

Examples of quality inspections on stamped metal parts:

- Material Thickness

- Hole Sizes

- Length and Width

- Angles

Industry-standard quality tools along with customized gauges designed and built by Ultra are utilized for precise measurements. In-house calibration is performed on a regular basis to ensure quality tools maintain their accuracy.

Value-Added Operations

This area utilizes manual and automated processes to maintain the quality and cost goals of metal parts during assembly, inspection, and packaging. Computerized workstations provide detailed instructions for the metal parts, proper equipment settings, and expected production rates to ensure customer delivery goals are met.

A variety of equipment in this department performs welding, inserting, tapping, drilling, and washing operations. And with four robotic welders, we can guarantee increased production output and improved weld quality and precision.

Ultra as a one-shop supplier will offer these benefits:

- Reduced times to part completion

- Design out costs & improve quality

- Dedicated Customer Service Team

Case studies

Delivering Cost-Savings for a Metal Stamped Part

This involved adopting a new way to manufacture the shaft component of this part. And providing assembly of the final part in the stamping press with a progressive die.

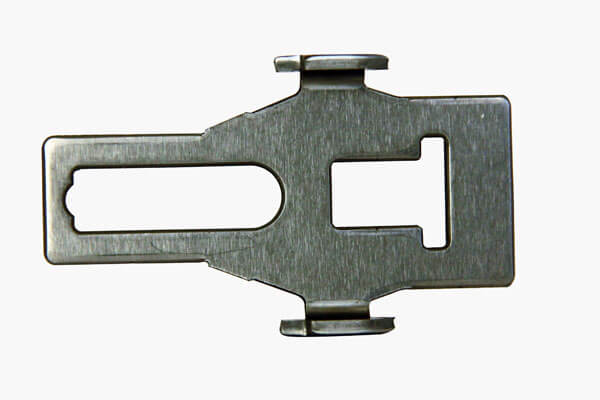

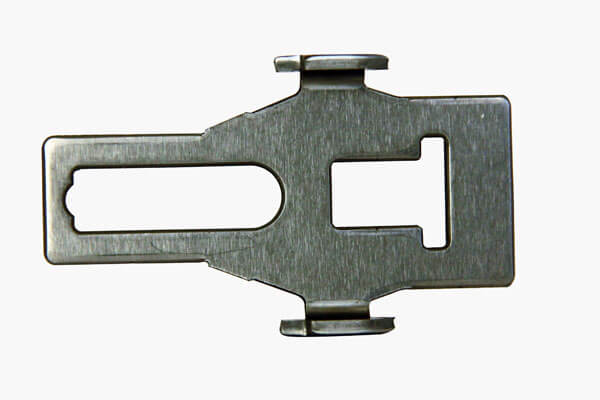

Read moreAchieving Manufacturing Cosmetic Standards

This stainless steel part is metal stamped in our 800-ton press using a 144-inch progressive stamping die that successfully removes sharp edges and cleans the surface areas.

Read more