Delivering cost-savings and repeatability

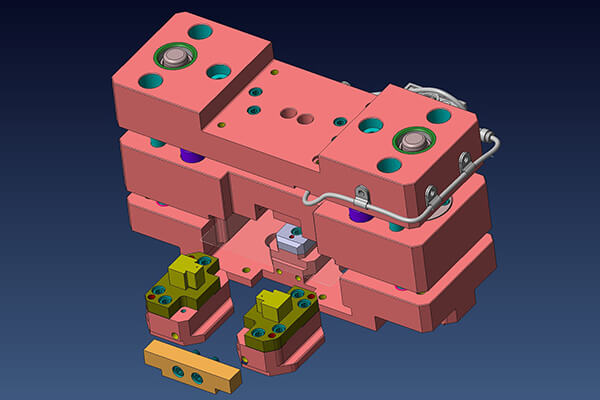

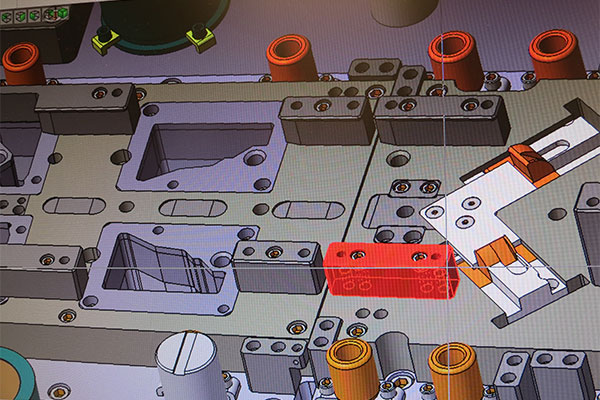

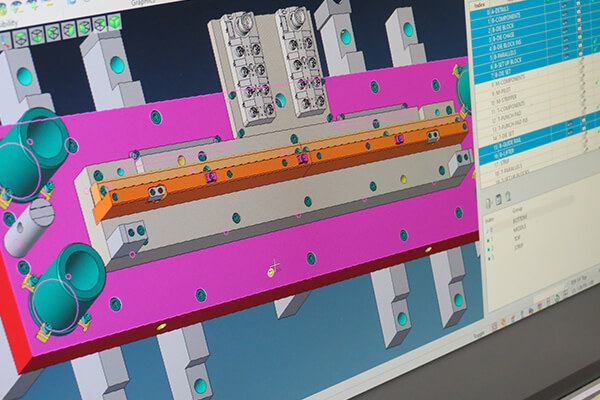

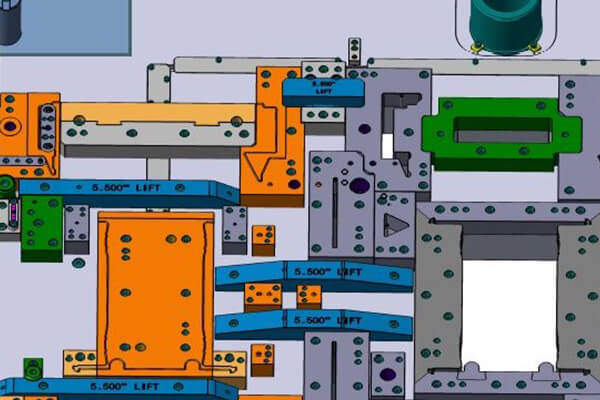

We partner the hands-on manufacturing experiences of our die designers with VISI-Design 3D software to establish a feasible, reliable, and quality design for your production tooling. Our comprehensive design process evaluates multiple factors from material type, part specifications, projected volumes, and equipment requirements to ensure the die will perform correctly for the long-term.

From design-to-delivery we adhere to a New Product Introduction (NPI) process. We utilize ERP-technology to communicate and document the required steps to the Engineers, Toolmakers, Quality Technicians, and CNC Machinists. This detailed and customized process ensures your cost, quality, and delivery goals will be attained during full production.

Our Die Design Capabilities

- Design single-hit and progressive dies

- Design customized fixtures and gauges for in-house processes

- Provide comprehensive assistance from estimation to production

- Design customized tooling for prototypes

- Evaluate production operations and identify methods to improve functionality

- ISO 9001:2015 certified facility

- Perform detailed manufacturability analysis

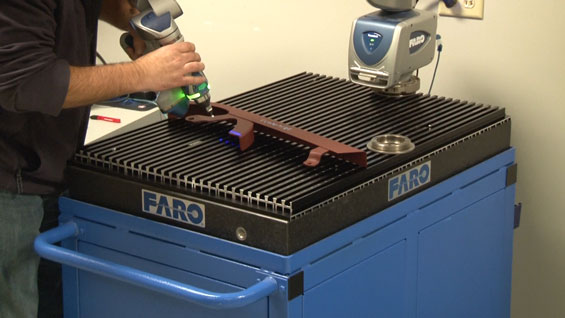

- Reverse engineering services with Faro Arm technology to precisely measure and 3D software to simulate production

Die Design Commitment

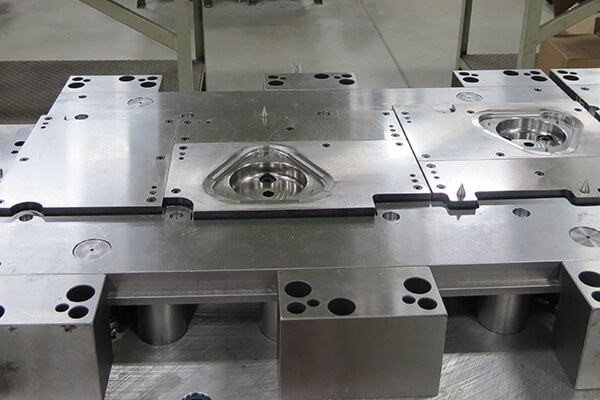

Designing is a highly technical process that requires patience and attention to detail. It is our hands-on manufacturing knowledge and emphasis on innovation that sets our design team above the others. A die is a valued investment and our goal is to design a robust die that consistently produces high-quality parts.

Die Design Technology We Use

VISI-Design 3D software

VISI-Design 3D software provides a step-by-step process to successfully create a design print for a single tooling die that often contains hundreds of components and multiple operations. Simulated production runs allow the designers to verify what does and does not work in the tooling die before building costs and time are actually incurred. This system optimizes the designs to improve manufacturing productivity.

3D Measurement

The Faro Arm utilizes high-precision 3D technology to capture, measure and analyze the dimensions of a physical object at 560,000 points per second. This allows the Die Designers to handle more complex geometries and receive results quickly for shorter turnaround times.

Case studies

Meeting Design Challenges

The tabs on this lock washer were not forming correctly leading to production delays. Prototyping established a feasible manufacturing process that could metal stamp this part and its tabs to the design print.

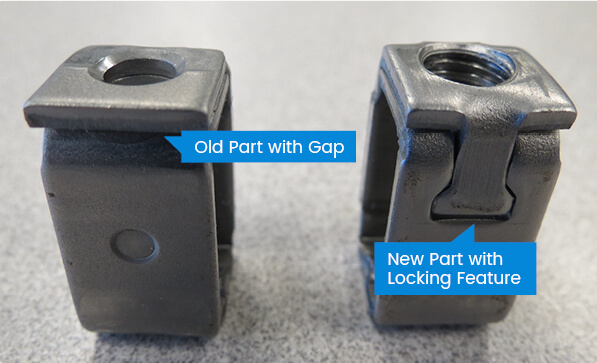

Read moreStreamlining Production and Improving Quality

This metal part was having quality issues and its production costs were increasing. A new locking feature corrected the quality issues and building a more efficient progressive stamping die reduced costs.

Read moreForming a Metal Part With the 800-Ton Press

This ramp is manufactured on a progressive die that includes only ONE forming station to complete that stage of production. A detailed finishing process includes deburring and polishing.

Read more →Providing Innovative Tooling Dies

This project focused on improving the performance and quality of the cutting operation located in this production tooling. This also included an effort to increase accessibility of this cutting component.

Read more →Precision Metal Fabrication Components

Established a metal bending and metal cutting process to produce components for a fan assembly requiring a precision fit to operate as designed.

Read more →Robotic Welding a Stamped Metal Part

Improvements were needed to the welding process to maintain a high-quality and functional metal part. And a more efficient method needed to be implemented to reach acceptable cost levels.

Read more →Prototyping to Production

A successful transition from a two-piece welded assembly to one-piece aluminum frame with 21 hardware insertions required the manufacturing expertise of our Die Designers and Toolmakers.

Read more →