Our customer, a Global Industrial Automation Manufacturer, utilizes metal parts for applications they design and produce. They are looking to improve the traceability of aluminum base plates Ultra metal stamps as they arrive at various manufacturing facilities with barcodes and other text.

Laser marking is an efficient and effective way to meet this customer’s newest requirements. And to keep this service in-house for higher quality and more consistent results Ultra called on our Automation Technician, Andrew, to create a customized laser marking process for aluminum base plates. He recognized this was the perfect time to improve the current process of verifying that 20 PEM nuts are inserted correctly in the plates.

Ultra currently metal stamps four different models of this aluminum base plate. The goal was to create a process focused on productivity, precision, and reliability that can both verify the PEM nuts and perform laser marking.

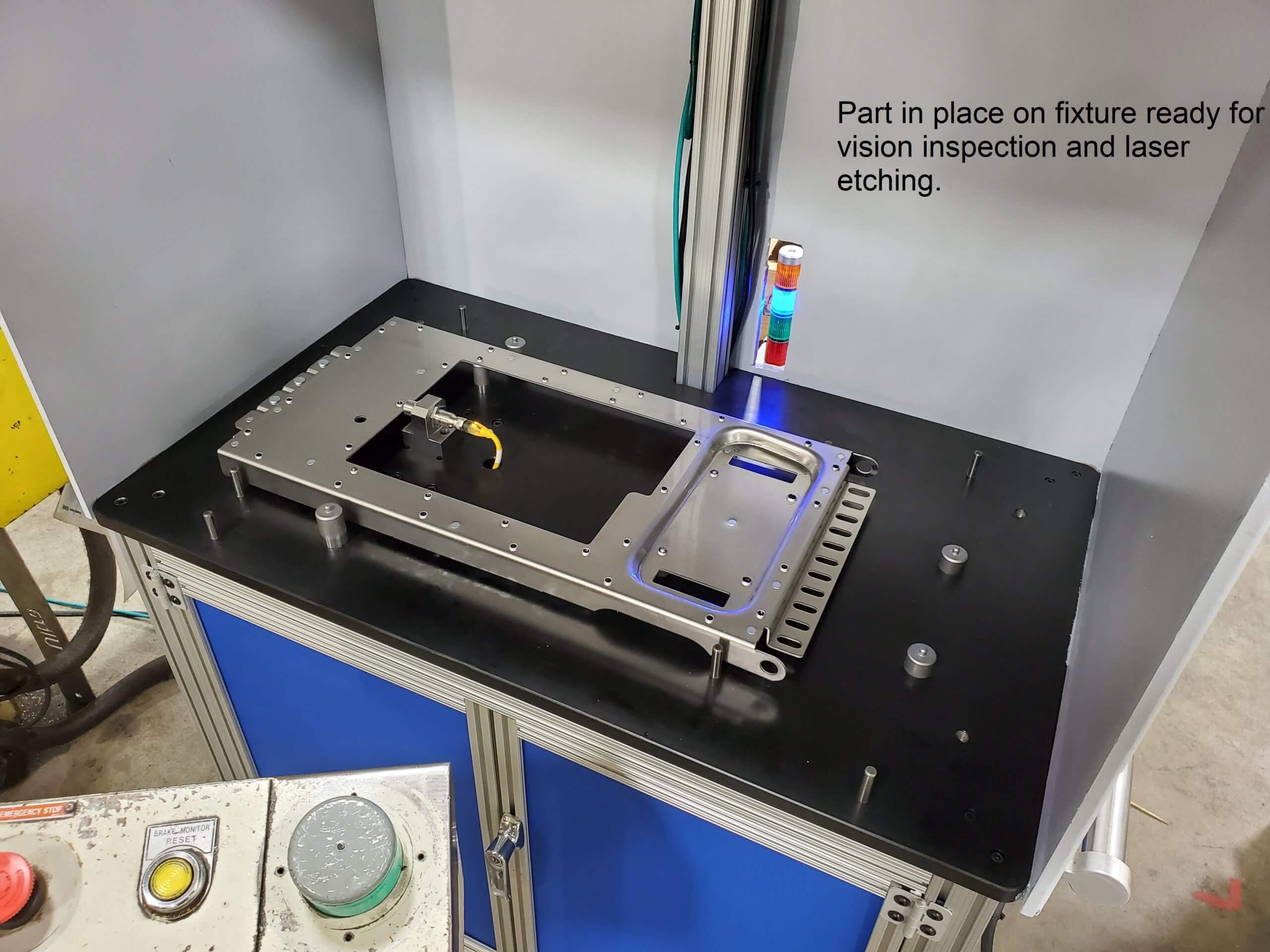

Andrew designed and built an automated system to perform these two operations on the aluminum base plates after metal stamping is completed.

- Check for the presence of the 20 PEM nuts utilizing dual vision cameras and sensors. A picture is taken and if all PEM nuts are present then the process can continue. This operation is completed within 2 milliseconds.

- A laser etches a barcode and specified text onto the underside of the metal part.

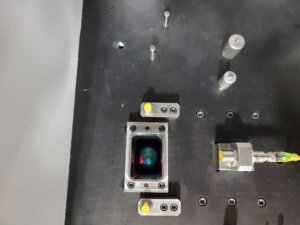

Dual vision sensors check for the presence of PEM nuts. If all are present a signal is sent to the laser to etch the bar code and text.

The laser that performs the marking.

The completion of the laser marking for this aluminum base plate.

A laser, a workstation computer, the vision cameras, a safety controller, and a PLC (Programming Logic Controller) are communicating with each other on the manufacturing floor to provide real-time inspection results to the press operators.

This technology-focused operation is providing a more consistent, streamlined, higher quality, and more accurate process.