Are you looking for ways to cut costs on a current part? But don’t want to risk the quality? Jumping from one ineffective cost-saving method to the next can be time-consuming and adds inconsistency into the production cycle.

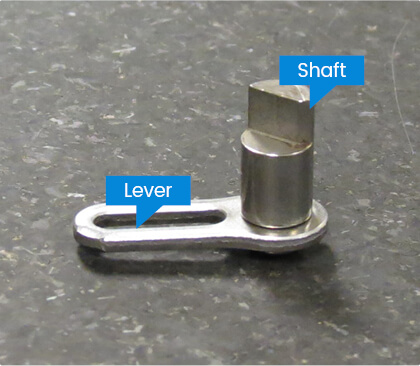

Progressive dies build a solid foundation for long-term and continuous cost-savings. These dies can deliver complex parts with their multiple stations. Progressive dies have the capability when designed and built correctly to perform assembly operations; streamlining your entire production process. We did this exact thing for an automotive manufacturer and their decomp metal part shown here.

A pair of bowl feeders oriented and fed the shaft pieces into the die for assembly with the lever pieces. Previously, it was an inefficient operation involving physically moving the lever parts from the stamping department to value-added for assembly with the shaft pieces. The in-die assembly effectively eliminated the need for secondary operations and created an all-inclusive production process.

This short video displays this progressive die in action.