Case Study: Streamlining Production and Improving Quality

Customer

Industrial Automation Manufacturer

Part

Box Lug

Manufacturing Issues

Their current production process included too many steps and was increasing costs.

Misalignment on the top of the part was decreasing the quality and performance of

the inner threads.

Customer’s Goals

Reduce production time with an improved manufacturing method.

Eliminate the thread quality issue without significantly increasing costs.

Manufacturing Process

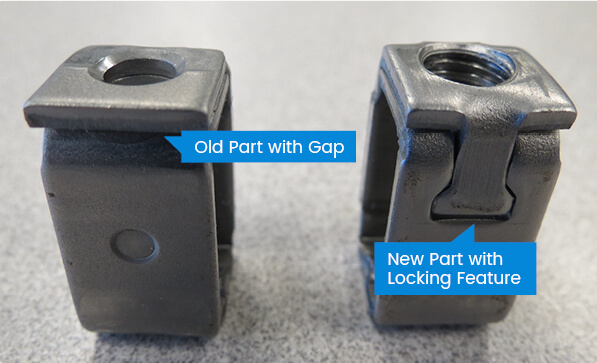

First, Ultra focused on fixing the alignment and thread quality issues which led to a minor redesign of box lug. We introduced a locking feature that minimized the gap and created a more secure fit. This can be seen on the box lug located on the right-hand side of the picture.

Second, Ultra addressed the increasing production times and that started with evaluating the tapping operation that was taking place after metal stamping. With the redesign of the box lug, it was the ideal time to add the tapping operation into the metal stamping process. Our team of Die Designers created a new progressive stamping die with two new operations.

Install the locking feature in one new station.

Install the tapping operation in another new station.

This resulted in the metal stamping of 1,680 box lugs per hour on the press. After this production is completed, Ultra manages the heat treating and plating services for this metal part as well. The production process is completed at our facility with final inspection and packaging for delivery.

Customer Outcome

Production times and costs were reduced when the tapping operation was added to the new progressive stamping die.

The new locking feature improved the alignment of the part which allowed the inner threads to function as designed.

Other Case studies

Improving the Production Process

The (6) bends and (8) holes require a detailed and customized fabrication process to match the design print. Hardware insertion and final inspection complete this production process.

Read more →Reducing Costs with a Progressive Stamping Die

Production costs were increasing because a splash guard and (6) drainage slots were added to the part’s design to meet safety requirements. The part’s length changed with these newly added features and made the existing die unusable.

Lower production costs for the fuel filler by utilizing a more efficient production process. Ensure the new features maintain the overall functionality of the fuel filler cup.

Read more →Outdoor Power Equipment Metal Stamping Case Study

Manufacturer of Rotary Lawn Mower Blade Sharpeners and Balancers for the Outdoor Power Equipment Industry

A recommendation from their previous supplier brought Outdoor Power Equipment Manufacturer’s leaders, Gerd & Erik Bauer, to Ultra’s front doors to continue production of their lawn mower blade sharpener.

Read more →Prototyping to Production

A successful transition from a two-piece welded assembly to one-piece aluminum frame with 21 hardware insertions required the manufacturing expertise of our Die Designers and Toolmakers.

Read more →Meeting Design Challenges

The tabs on this lock washer were not forming correctly leading to production delays. Prototyping established a feasible manufacturing process that could metal stamp this part and its tabs to the design print.

Read more →