Case Study: Reducing Costs with a Progressive Stamping Die

Customer

Motorcycle Manufacturer

Part

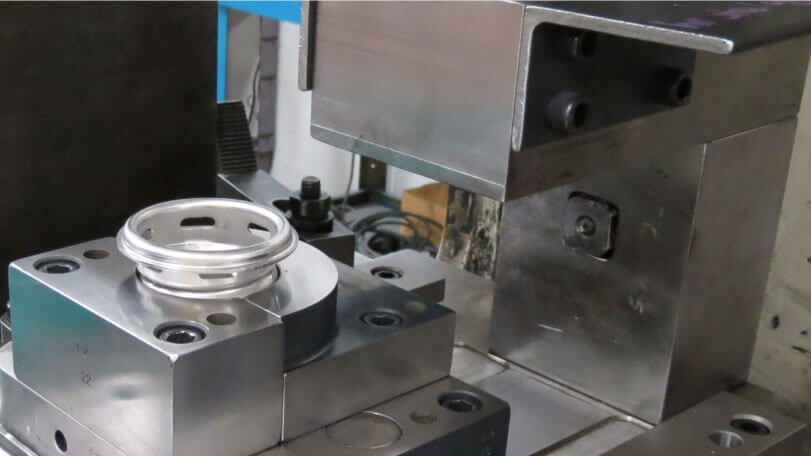

Fuel Filler Cup

Manufacturing Issue

Production costs were increasing because a splash guard and SIX drainage slots were added to the part’s design to meet safety requirements.

Customer’s Goals

Lower production costs for the fuel filler by utilizing a more efficient production process.

Ensure the new features maintain the overall functionality of the fuel filler cup.

Redesign Process

It was determined that utilizing a progressive die to produce this part would cost less per part veruss the customer's current hand-fed manufacturing process. Ultra designed and built a new progressive die with multiple stations that produced the overall shape, threads and six drainage slots of the fuel filler cup. In fact, it required two separate stations to accurately form the threads into the cup. The six drainage slots were pierced from the inside to eliminate burrs and meet the customer’s cosmetic standards. With our 800-ton press and its 168” bed we were able to design this die to perform a majority of the operations during stamping, thus reducing time and money spent on secondary operations.

The final operation was the installation of the splash guard that was critical for safety purposes. Our smaller, hydraulic press accurately placed and secured the splash guard using less labor.

Customer Outcome

Ultra’s customized manufacturing process reduced costs and even increased production rates.

The fuel filler cup matched the customer’s safety requirements.

The customer trusts our expertise and services to metal stamp two different sizes of this design for their assembly needs.

Other Case studies

Achieving Tight Tolerances Metal Stamping

Collaborative discussions with the customer helped Ultra fully understand the functionality and features of the thrust ring. It was identified that the part’s tabs required a tight tolerance of no more than .062” to achieve correct alignment with threads during the multi-assembly process.

Read more →Delivering Cost-Savings for a Metal Stamped Part

This involved adopting a new way to manufacture the shaft component of this part. And providing assembly of the final part in the stamping press with a progressive die.

Read more →Quality Controlled Manufacturing Process

With a manufacturing process like this that utilizes our in-house services and outside suppliers, continuous AQL inspections are required to verify the metal part is defect-free.

Read more →Achieving Manufacturing Cosmetic Standards

This stainless steel part is metal stamped in our 800-ton press using a 144-inch progressive stamping die that successfully removes sharp edges and cleans the surface areas.

Read more →Improving the Production Process

The (6) bends and (8) holes require a detailed and customized fabrication process to match the design print. Hardware insertion and final inspection complete this production process.

Read more →