Case Study: Achieving Tight Tolerances in Metal Stamping

Customer

Motor Vehicle Parts Manufacturer

Part

Thrust Ring

Manufacturing Issues

Unable to consistently maintain the inside diameter during production.

Unable to manufacture the tab features to match the design print.

Customer's Goals

Select a high-quality, reliable supplier to accurately metal stamp this part to match its design. The thrust ring needs to precisely fit in a specified position and achieve perfect thread alignment during operation.

Ideally, it would be a cost-savings to assemble this thrust ring and its associated components at the facility of the metal stamper.

Design and Manufacturing Process

Collaborative discussions with the customer helped Ultra fully understand the functionality and features of the thrust ring so that it we could produce this part to print without issues. The part’s tabs required a tight tolerance of no more than .062” to achieve correct alignment with threads during a multi-assembly process. A total of seven individual parts needed to function individually and together for the final mechanism to work properly.

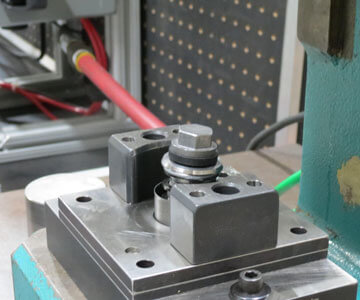

Ultra designed and built a progressive stamping die based on coining operations because this method is better at attaining the tighter tolerances and maintaining the inside diameter. We built a station after forming was complete to keep the ring open to its specified inside diameter for the remainder of the production process. This then allowed for greater precision in the formation and placement of the tabs; including in-die adjustment of the tabs if needed. The tolerance of no more than .062 on each tab was critical to eliminate backlash during assembly with the threaded part.

Ultra also provided the customer with the opportunity to assemble the final mechanism at our facility for continued consistency and quality. A step-by-step manual assembly process took place in our Value-Added Department. Our Tool and Die Department designed and built customized inspection equipment to ensure the final mechanism operated correctly.

Final Assembly and Inspection Process:

We also provided the customer with the opportunity to assemble the final mechanism at Ultra for continued consistency

and quality. A step-by-step manual assembly process took place in our value-added department. Our tooling

department designed and built customized inspection equipment to ensure the final mechanism operated correctly.

Customer Outcome

The custom progressive stamping die continuously produces thrust rings that meet the design print.

A majority of the manufacturing process is performed at Ultra for quicker lead times, greater consistency and higher-quality results.

Other Case studies

Customizing Parts with Metal Fabrication

Providing high-quality and durable metal components for the manufacturer to customize assemblies as needed at their production facility.

Read more →Precision Metal Fabrication Components

Established a metal bending and metal cutting process to produce components for a fan assembly requiring a precision fit to operate as designed.

Read more →High Volume Metal Stampings

A crimping operation was added to the metal stamping process to lower costs for this product line. And utilizing only two progressive stamping dies to produce five parts was another cost-savings.

Read more →Metal Part with Weight Requirements

The total weight of this part and the positioning of its legs are critical to its performance. An automated inspection system was created to verify both of these features are met after metal stamping has been completed.

Read more →Robotic Welding a Stamped Metal Part

Improvements were needed to the welding process to maintain a high-quality and functional metal part. And a more efficient method needed to be implemented to reach acceptable cost levels.

Read more →