Case Study: Delivering Cost-Savings for a Metal Stamped Part

Customer

Automotive Manufacturer

Part

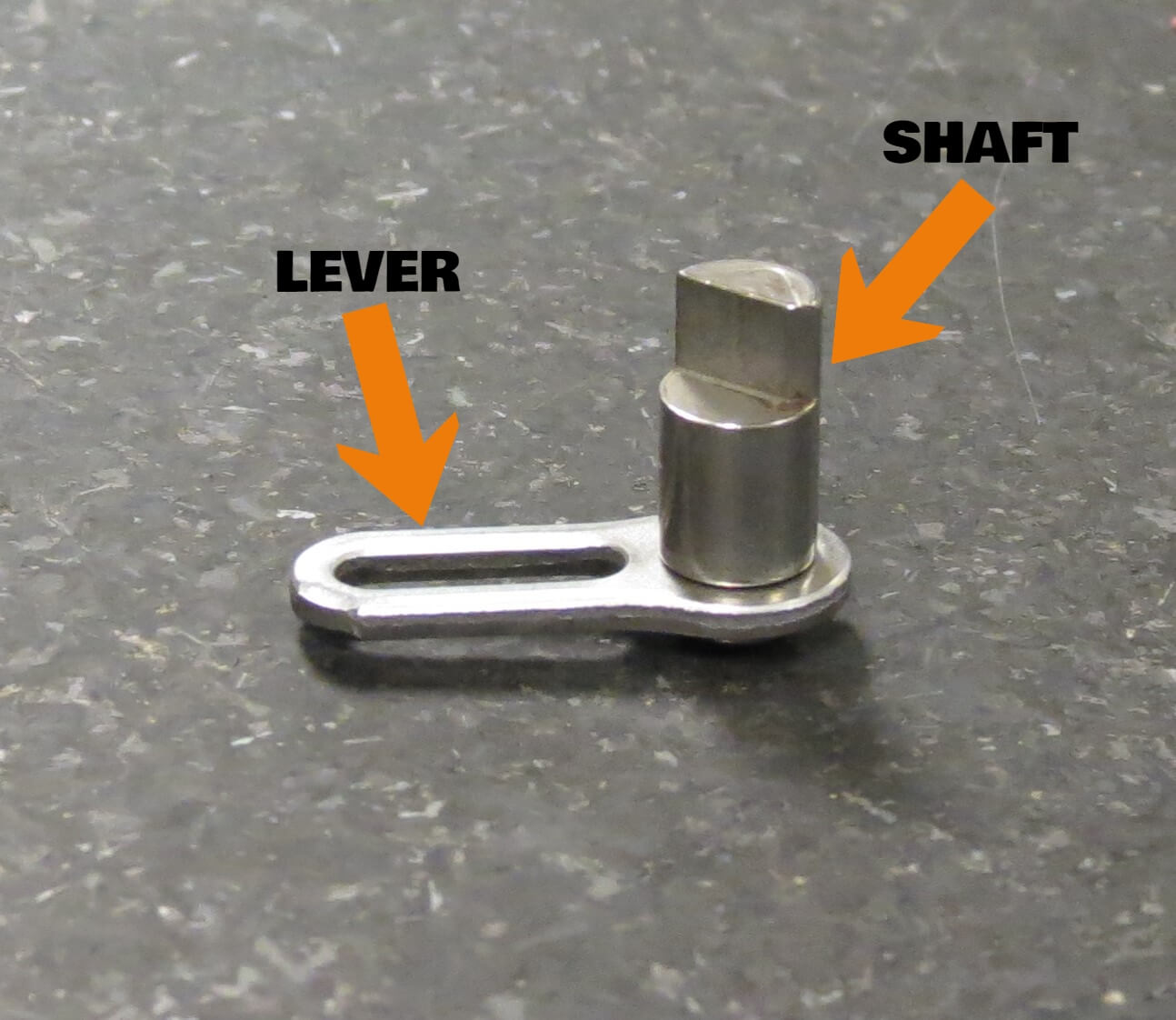

Decomp

Manufacturing Issues

Costs and production times were rising for the shaft component of this part.

Assembly costs were rising to unacceptable levels and operations were inconsistent.

Customer’s Goal

Reduce the costs of the shaft piece and simplify the manufacturing process.

Minimize the assembly costs utilizing a more efficient method that meets quality and design standards.

Manufacturing Process

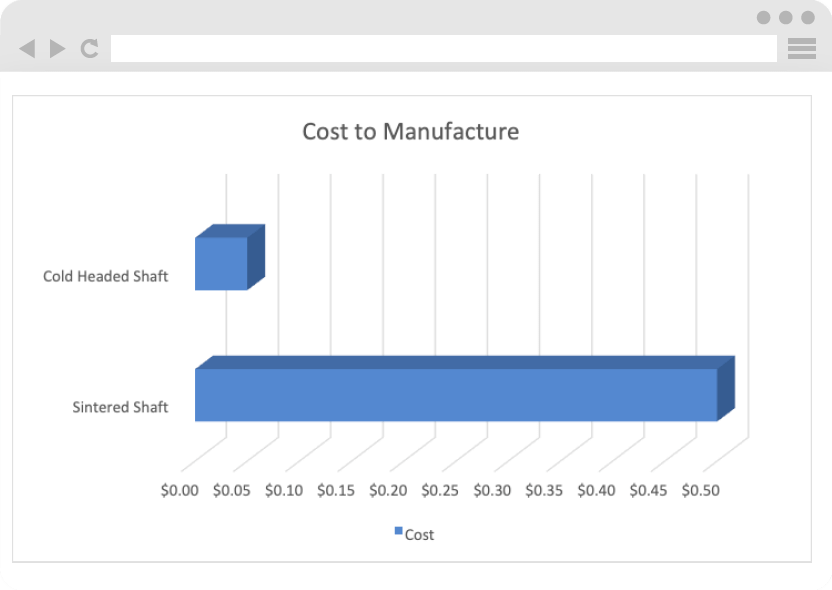

The shaft component was currently being produced as a sintered metal piece to attain the correct form. This was a time consuming and costly process.

Ultra recommended manufacturing the shaft as a cold-headed piece going forward. This process would produce the shaft more quickly and at a significantly lower cost. The strength of the shaft would also be increased and eliminate fracturing issues during assembly.

We next addressed the assembly issues and our focus turned to the metal stamping process. Ultra determined it was most cost-effective to design and build a new progressive stamping die to consistently assemble this part and meet the customer's production demands.

FIRST, the lever component is metal stamped in our Minster 100-ton press.

SECOND, the shaft and lever components are assembled. The bowl feeders, shown below, orient and feed the shaft components into the progressive die for assembly with the lever components.

The progressive stamping die performing assembly of the shaft and lever components in the 100-ton press.

Customer Outcome

Experienced a 90% decrease in the cost of the shaft piece.

Lead times were improved with assembly operations now taking place in the stamping press.

The stamping press produces 4,800 of these parts per hour.

Other Case studies

Precision Metal Fabrication Components

Established a metal bending and metal cutting process to produce components for a fan assembly requiring a precision fit to operate as designed.

Read more →High Volume Metal Stampings

A crimping operation was added to the metal stamping process to lower costs for this product line. And utilizing only two progressive stamping dies to produce five parts was another cost-savings.

Read more →Metal Part with Weight Requirements

The total weight of this part and the positioning of its legs are critical to its performance. An automated inspection system was created to verify both of these features are met after metal stamping has been completed.

Read more →Robotic Welding a Stamped Metal Part

Improvements were needed to the welding process to maintain a high-quality and functional metal part. And a more efficient method needed to be implemented to reach acceptable cost levels.

Read more →Achieving Tight Tolerances Metal Stamping

Collaborative discussions with the customer helped Ultra fully understand the functionality and features of the thrust ring. It was identified that the part’s tabs required a tight tolerance of no more than .062” to achieve correct alignment with threads during the multi-assembly process.

Read more →