Tool and Die Making powered by CNC technology and experience

Our Toolmakers build and maintain innovative metal stamping dies that reduce costs, increase repeatability and deliver high-quality, defect-free parts.

Our Machinists utilize their extensive tooling knowledge and technical skills to operate CNC and Wire EDM equipment that delivers precision die components. The Tooling Department continuously works with Die Design and Metal Stamping to ensure metal stamping dies produce parts to print consistently and without problems.

Tool and Die Capabilities

- Design-and-build progressive stamping dies for OEM’s and in-house metal stamping jobs

- Apply in-die sensor technology to improve production methods and protect metal stamping dies

- CNC Machining delivers precision die components and die blocks with greater speed

- Achieve tighter tolerances, greater accuracy and more complex shapes for tooling die components with Wire EDM equipment

- Attain production tolerances within .001" with the ability to achieve .0002" as needed

- Perform die try-outs and first-run production in (13) metal stamping presses with 45 to 800 ton capabilities

- Custom-build tooling for metal fabrication prototyping and production

- Design and build gauges and metal fixtures for inspection, production and assembly purposes

- Perform preventative die maintenance to prolong die longevity and performance

Our Tool and Die Services

- Blanking

- Cut Off

- Forming

- Shaving

- Compound Operations

- Pancake Die

- Side-Cam Die

- Curling

- Drawing

- Honing

- Trimming

- Progressive Die

- Transfer Die

- Compound Die

Tool and Die Technology We Use

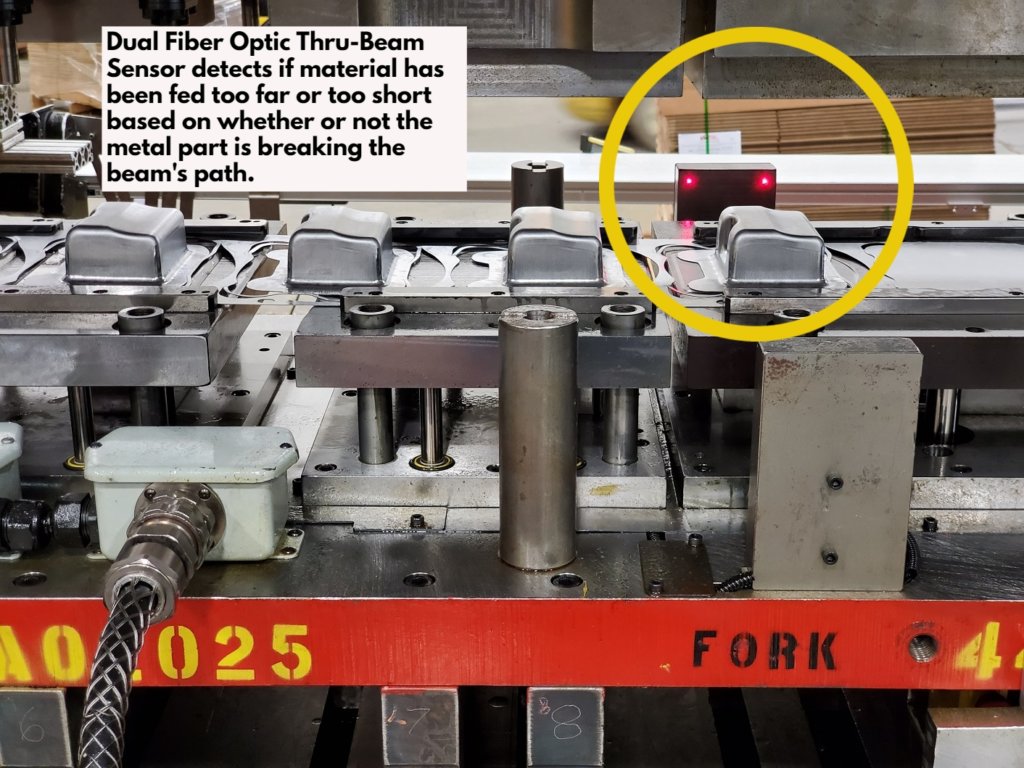

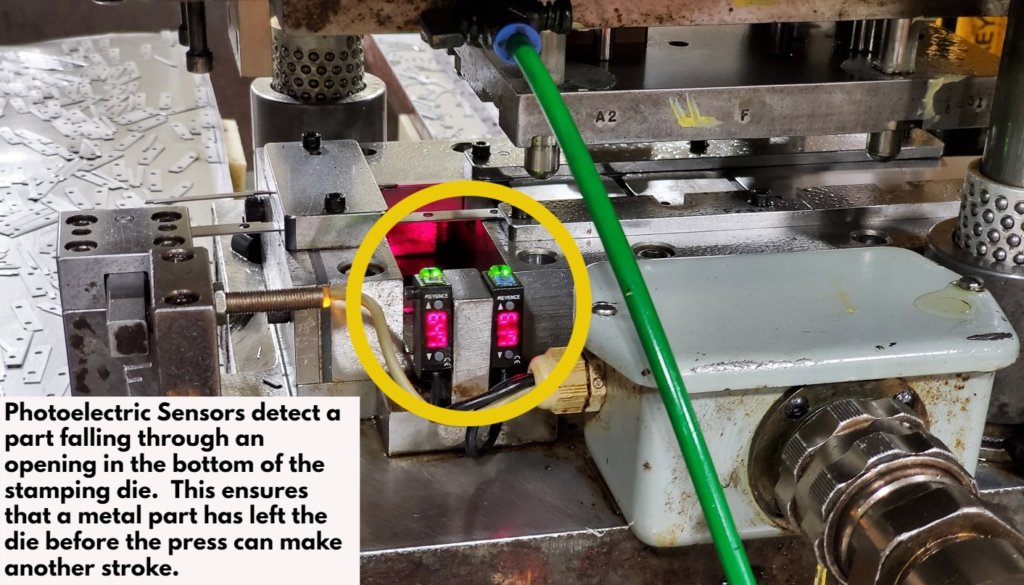

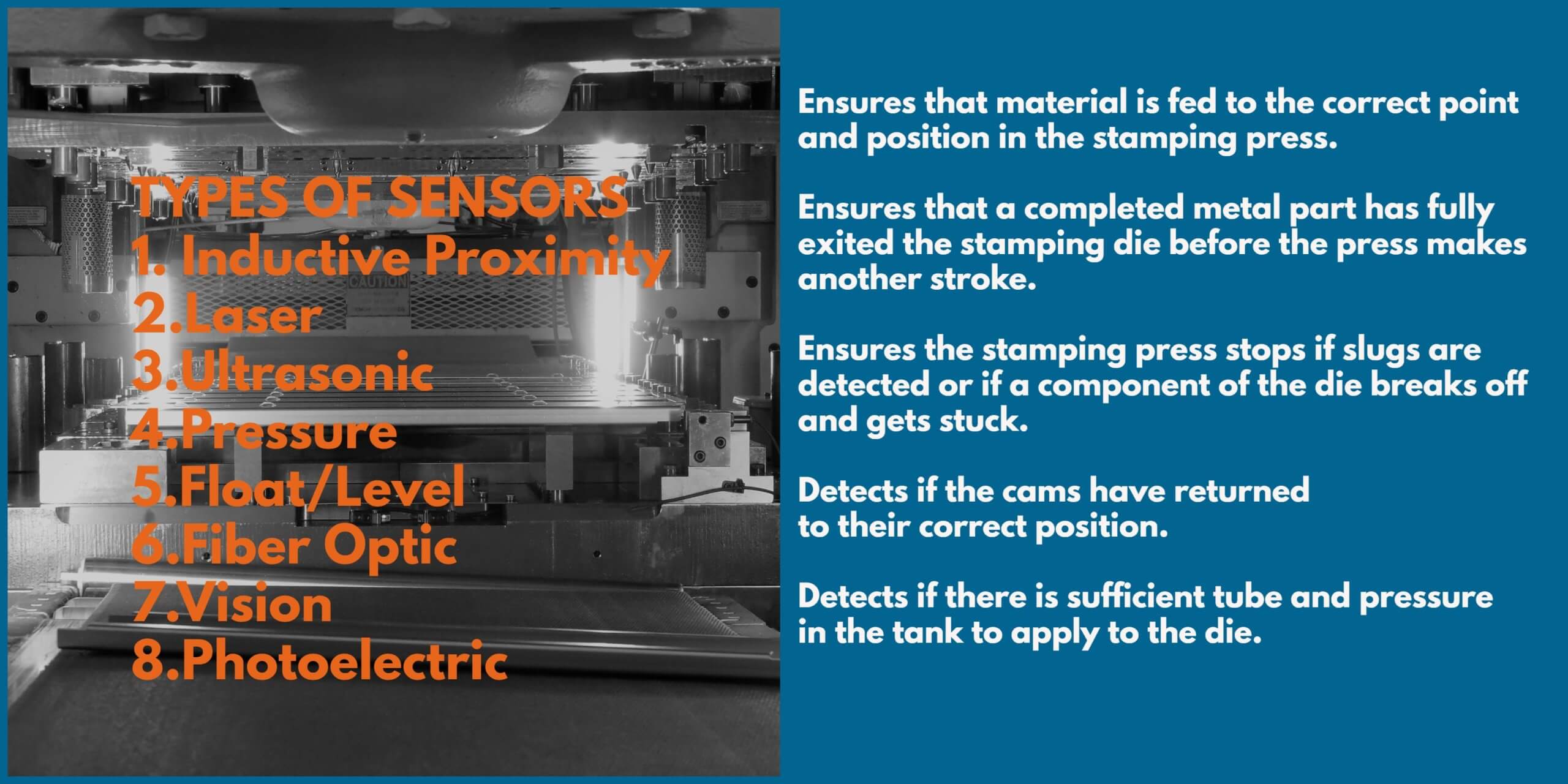

Sensor technology is utilized in every metal stamping die that we build for OEM’s and for production completed in Ultra’s stamping presses. Sensors protect the die and ensure it is functioning properly during set-up, throughout production, and during removal of the die from the stamping press.

The main goals for in-die sensors are to REDUCE and ELIMINATE the following issues.

- Stamping Die Crashes

- Rejected Metal Parts

- Downtime

- Quality Issues

A team of Die Designers, Toolmakers, Press Operators, and a dedicated Automation Technician are responsible for this sensor technology during metal stamping. Their main goal is to protect your most valuable production asset - the stamping die.

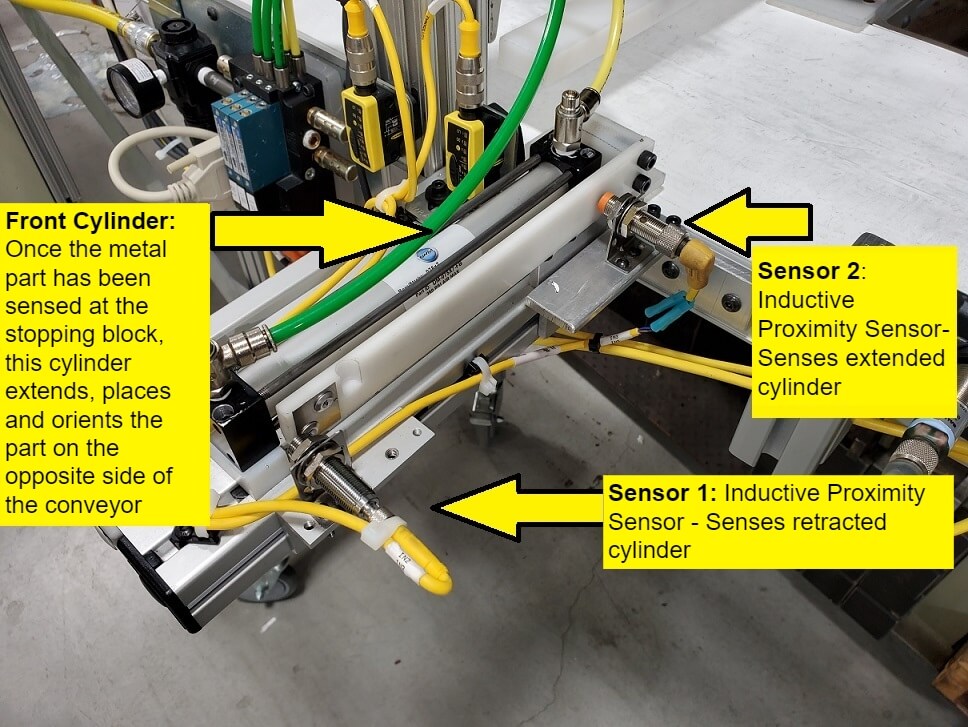

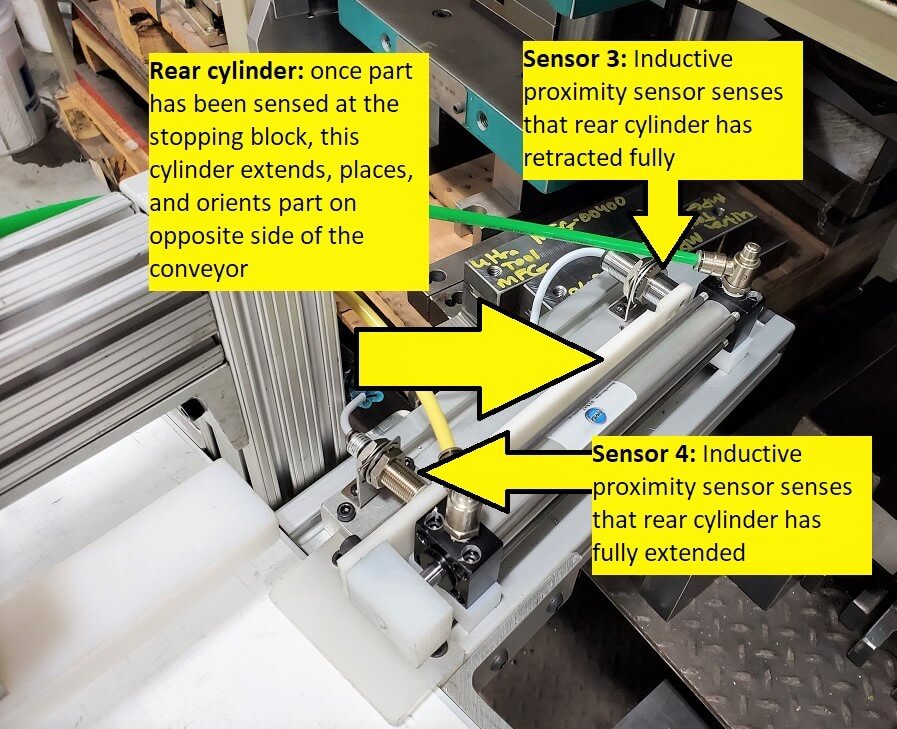

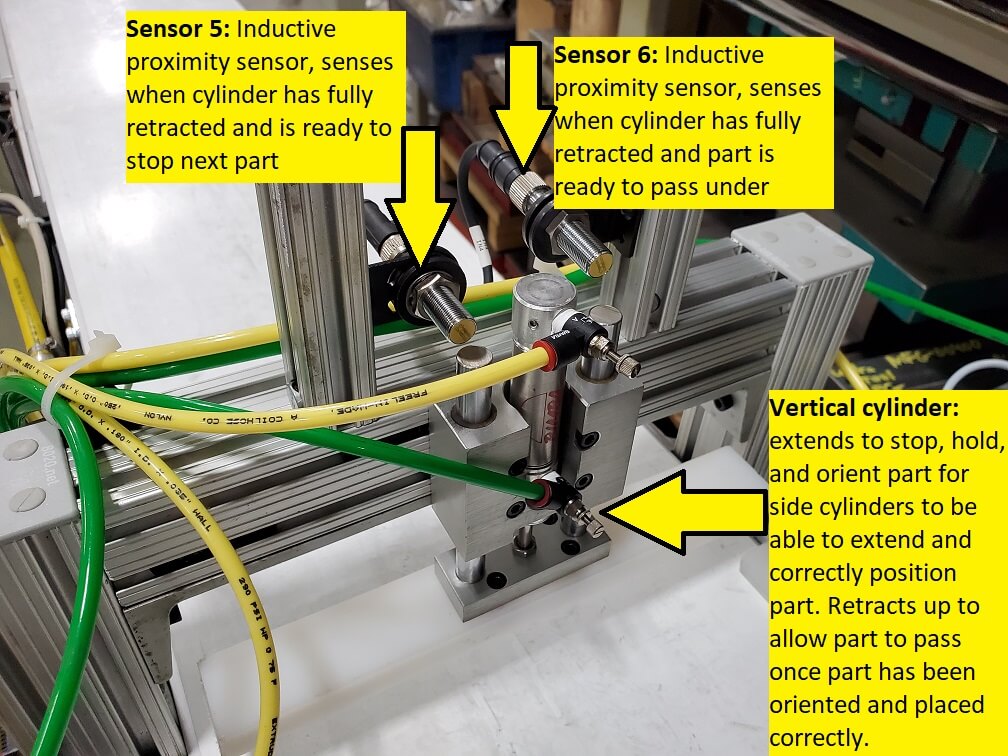

Detailed views of sensors in the press

These small, but powerful sensors establish and maintain consistent and quality metal stamping operations to meet your production goals.

Sensor technology is utilized at Ultra even after metal stamping has been completed. This technology continues to ensure that every process up to final delivery is completed on-time and to the customer’s specifications.

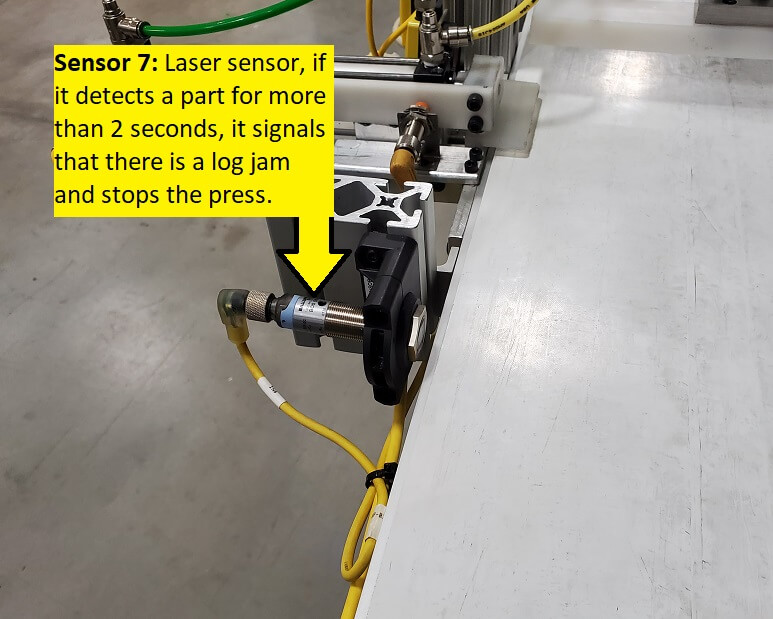

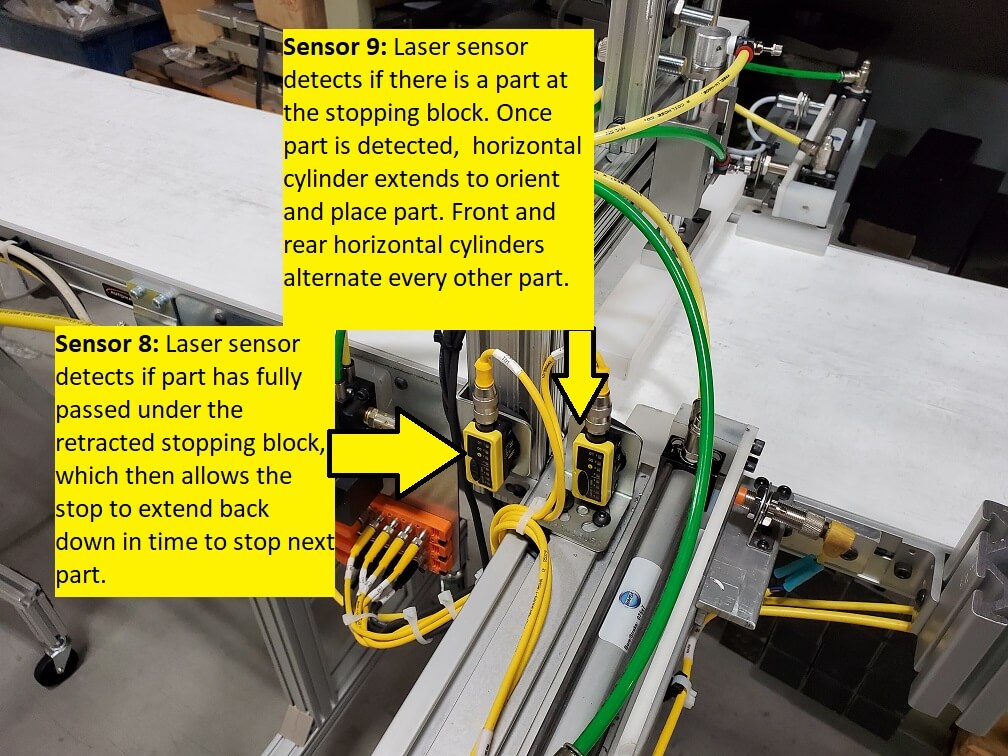

The sensor technology seen in this video controls and aligns these metal parts as they progress on the conveyor belt to the washing station. This automated system allowed us to increase the strokes per minutes in the 300-ton press and improve the production rate.

Watch technology deliver better results!

See how these sensors operate

#1

#2

#3

#4

#5

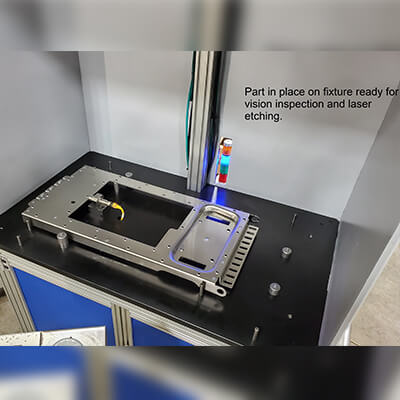

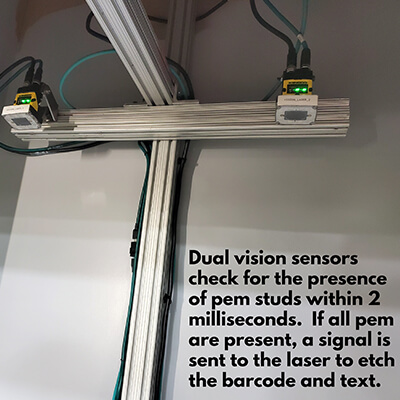

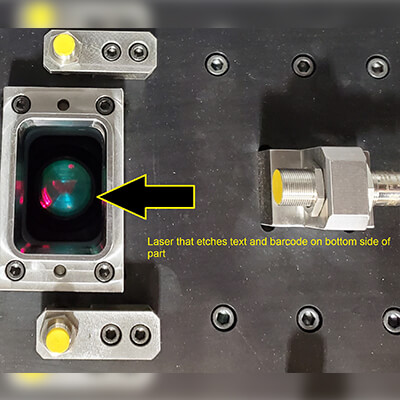

This sensor technology is utilizing vision sensors to verify 20 PEM studs are inserted and in the correct locations for industrial aluminum frames. Then a laser etches on a barcode and other critical text required by the customer. This system is set up to handle four different variations of this part including a frame up to 35 inches in length.

#1

#2

#3

#4

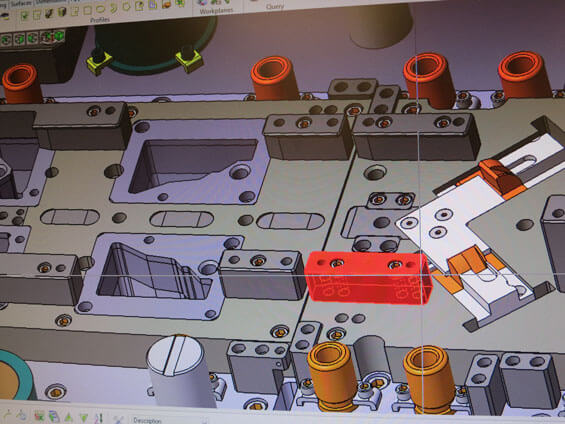

3D Design Software

We use state-of-the-art software by VISI-Design to create detailed design prints for metal stamping dies, production tooling, measuring gauges, and fixtures utilized on the manufacturing floor. This advanced design software allows our Die Designers to simulate production and verify what is and isn't feasible. It also more easily identifies potential issues in the design stage when changes are easier to perform and are less costly. Our pre-build meetings establish a cooperative approach with CNC machinists, Wire EDM operators, CNC Programmers, Designers and Toolmakers. This helps ensures stamping dies will consistently deliver metal stamped parts that match the design print.

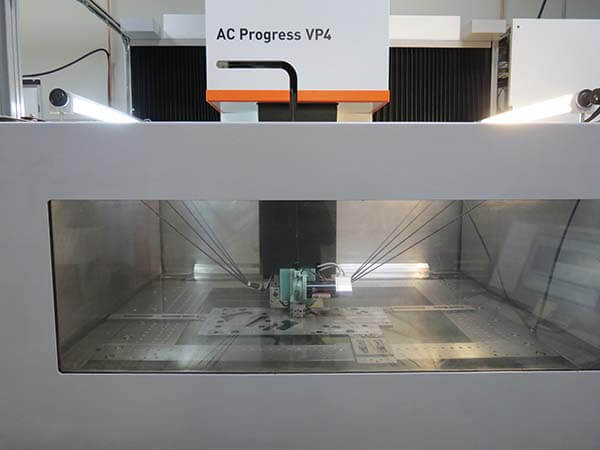

Precision CNC Machining

Detailed 3D computerized prints guide our CNC Machinists as they build precision die components and made-to-order fixtures and gauges. The print outlines the CNC tools to use to match specific tolerances, hole sizes, and other dimensioned features.

We utilize 3-axis CNC equipment like the Double Column Bridge Mill Feeler with a larger table size (55" x 85") that can handle larger die blocks and metal components. It's also more loader-friendly which improves turnaround times.

A dedicated space in the Tool Room with specific temperature and sanitary regulations maintains a consistent, high-quality manufacturing environment that houses our THREE Wire EDM machines . This CNC technology delivers less impact on the material when producing specific shapes compared to standard CNC machines and its turnaround is quicker with greater accuracy.

Capabilities

- Drilling

- Tapping

- Grinding

- Milling

- Boring

- (17) pre-set tools for standard operations

- (7) open tools for customized operations

Advantages of CNC Equipment

- Multi-tool changers manufacture complex parts quickly

- Repeat a detailed manufacturing process with 100% accuracy

- Achieve tighter tolerances

- Perform customized operations

- Quality of work superior to manual equipment

- Handle a variety of materials including bronze, gold and silver. Polymers such as ABS, polycarbonate and PTFE can also be used.

Die Maintenance

Our TOP priority in the Die Maintenance area is protecting your tooling investment. Regular preventive services are critical to longevity and performance. We can handle the most complex tooling dies and even pinpoint the source of a problem on tooling dies that weren't originally built at Ultra. Even with our 100% commitment to preventive die maintenance; crashes and mishits still do occur. And this is where our experienced Toolmakers can review a situation quickly, identify the issue and fix the tooling die in a timely manner.

Standard and customized checklists guide each tooling die that is serviced to ensure precision work is completed and that no component is overlooked. Customized criteria are determined by the tooling die's complexity and the type of production job. Stamping hits for each metal stamping job are maintained in our cloud-based ERP system and the Tool Room is alerted when service is required.

- Sharpen punches

- Polish

- Strip the coating and recoat

- Check tapping units

- Check sensors

- Regrease cams

- Cleaning

- Remove shavings

- Tighten screws

Case studies

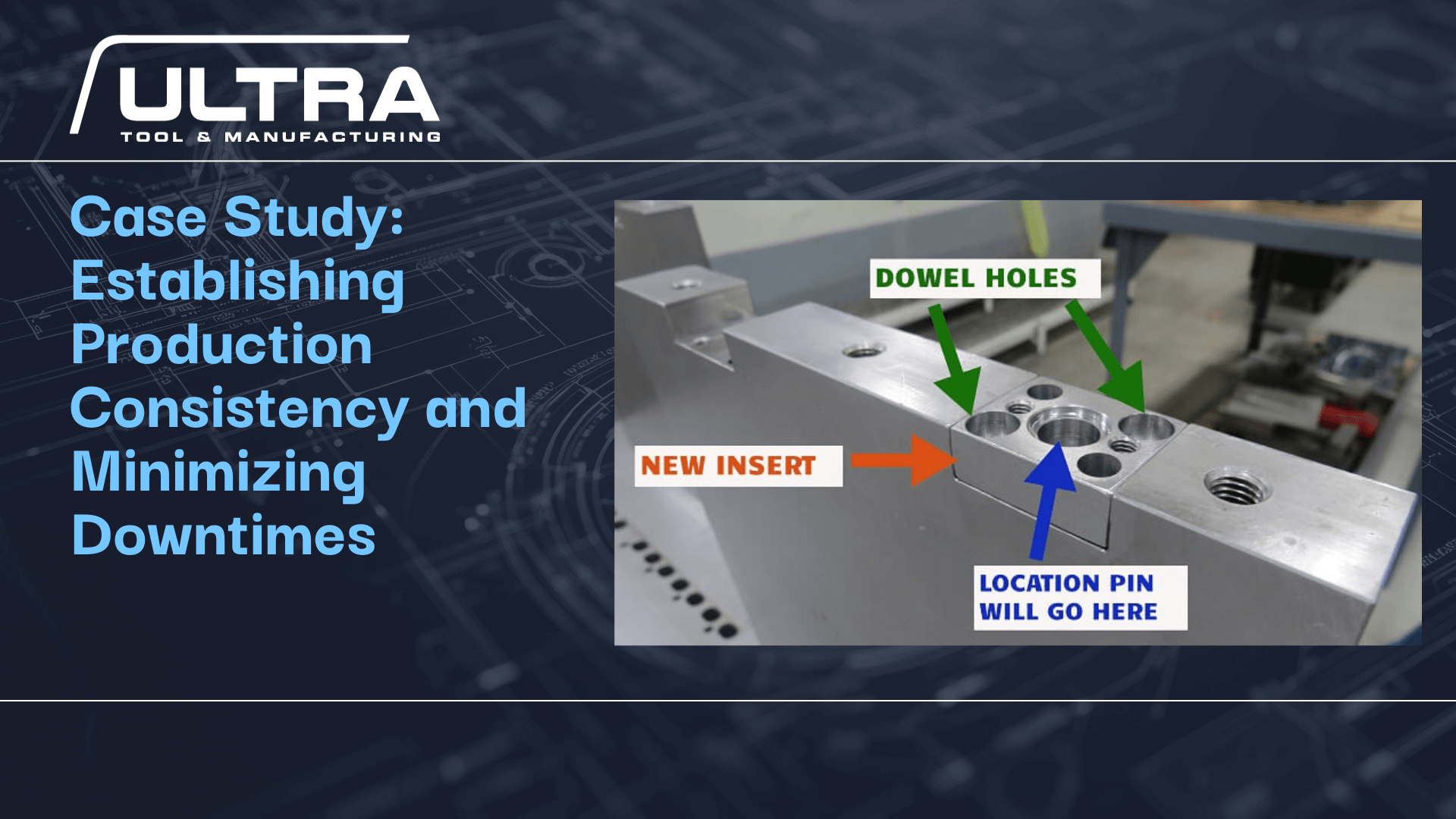

Establishing Production Consistency and Minimizing Downtimes

This metal part was having quality issues and its production costs were increasing. A new locking feature corrected the quality issues and building a more efficient progressive stamping die reduced costs.

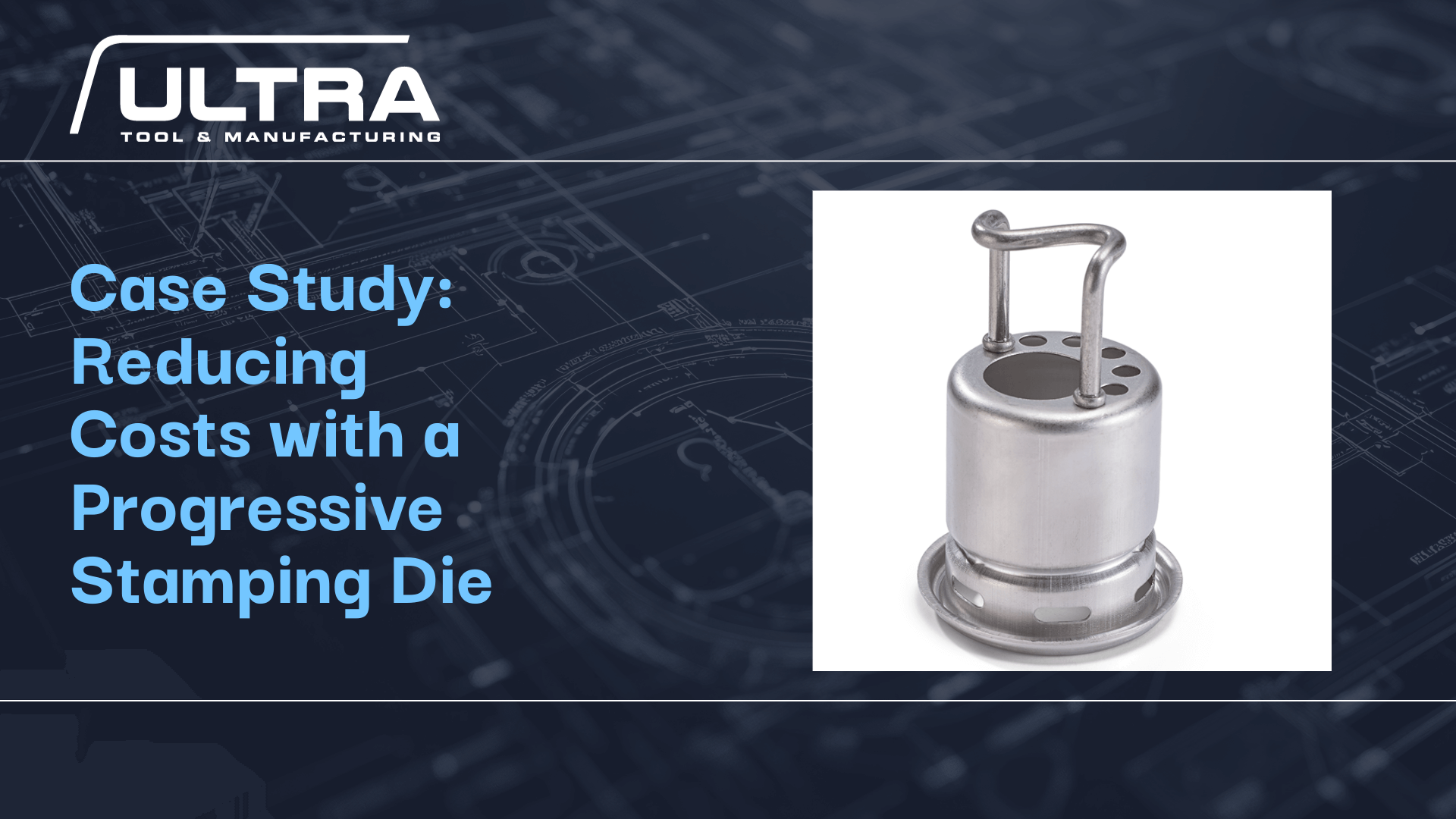

Read moreReducing Costs with a Progressive Stamping Die

Production costs were increasing because a splash guard and (6) drainage slots were added to the part’s design to meet safety requirements. The part’s length changed with these newly added features and made the existing die unusable.

Lower production costs for the fuel filler by utilizing a more efficient production process. Ensure the new features maintain the overall functionality of the fuel filler cup.

Read more