Customized metal fabrication services

Optimizing the skills and knowledge of an experienced fabrication team with high-quality equipment to deliver precision laser cut and formed metal parts.

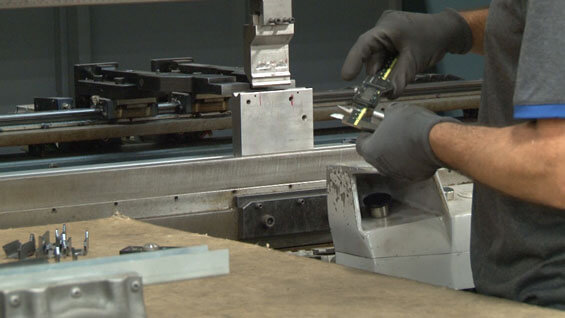

Metal fabrication capabilities are enhanced by the in-house services and equipment of our tooling and metal stamping areas. Quality inspections are followed from prototyping-to-production.

Our Metal Fabrication Capabilities

A focus on speed, quality and precision delivers simple to complex metal parts utilizing our Salvangini Fiber Laser. The dependability and customization available on the CNC Durma & Euromac Electric press brakes provide the ability to bend metal parts in varying sizes.

- Perform customized bends utilizing quality tooling built in-house

- Produce multiple metal components on-time and in spec for required assemblies

- Deliver prototyping services for metal stamped and metal fabricated parts

- Fiber laser cuts material thicknesses up to 0.700” for steel, 0.312” for stainless and .187” for aluminum, brass and copper

- Utilize advanced programming settings to laser cut complex designs

Metal Fabrication Techniques

- Punching

- Bending

- Forming

- Welding

- Machining

- Assembly

- Plating

- Painting

- Cutting

- Insertion

Metal Fabrication Technology We Use

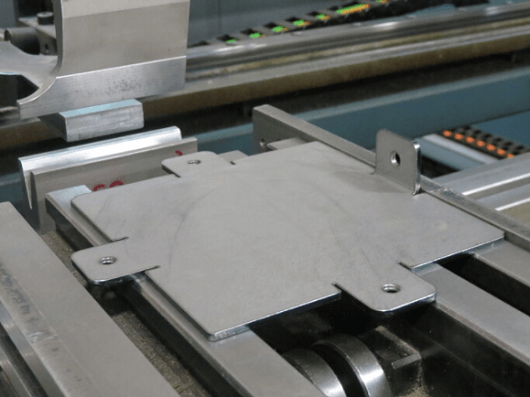

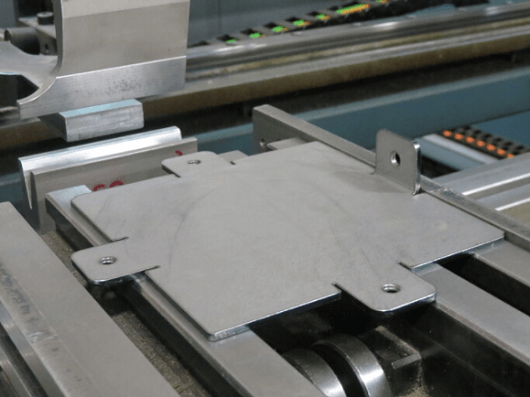

CNC Press Brake

We continuously push the press brake to do more as the demand for customization increases in metal components. Customized parts need customized tooling that fits precisely in the press brake and consistently operates correctly. Ultra delivers this customized tooling with our in-house designing capabilities and CNC equipment. This process improves lead times, consistency, and quality since all work is performed at Ultra by an experienced team of Die Designers, Toolmakers, CNC Machinists, and Fabrication Technicians. Ultra's manufacturing ERP-software monitors every hit on the press brake to ensure we are meeting production rates, provides alerts if issues arise, and communicates to the Fabrication Technicians when quality inspections are required.

Fiber Laser

Ultra's Fabrication team has extensive programming expertise on the Salvagnini L1XE to deliver precision metal parts again and again. Our technical expertise can easily identify when modifications to the laser are needed to meet the customized dimensions and tolerances of a design print. Ultra's focus on innovation drives our Fabrication Technicians to push the laser's capabilities and cut metal parts that our competitors turn away.

The Fladder Gryo/300 is an automated deburring machine that provides greater precision and repeatability versus hands-on deburring. And it delivers quicker turnarounds with reduced labor costs for your metal part. The multi-directional brushes allow the operator to control movement back and forth as well as the rotation; resulting in more consistent deburring in all directions. This automated deburring process improves our capability to continuously produce high-quality, smooth edges on each laser-cut part for easier assembly if required and improved part performance.

Quality

Ultra has an established process of quality inspections in Metal Fabrication to ensure the delivery of defect-free metal parts. This includes detailed measurements of prototypes to finished products for the various industries we serve.

PPAP (Pre-production approval process)

This is completed before full production can start on a new or redesigned metal part utilizing standard and customized quality criteria. PPAP includes a Layout Inspection – which measures every dimension of a metal part with micrometers, calipers, and automated equipment.

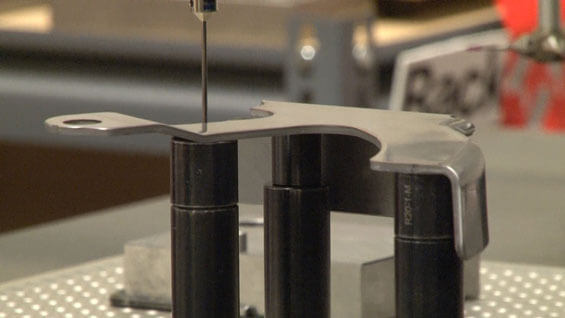

CMM – The probe of the Coordinate Measurement Machine precisely touches multiple points on a metal part that cannot be done by the human hand.

Faro Arm – This measurement equipment has highly accurate lasers that can scan 560,000 points per second providing the ability to quickly and precisely define a metal part's layout. This accelerates the pre-production process without sacrificing quality and details. It pinpoints inaccuracies allowing for design corrections before a part moves into full production.

1st piece inspection

This quality inspection is performed every time any stamping press performs an initial run of a metal part in a pre-determined quantity. This ensures the production process is set-up correctly to complete a production order without interruptions. During metal stamping operations, the ERP-system establishes the types of quality inspections as well as the frequency and the press operator is notified at their workstation.

Examples of quality inspections on stamped metal parts:

- Material Thickness

- Hole Sizes

- Length and Width

- Angles

Industry-standard quality tools along with customized gauges designed and built by Ultra are utilized for precise measurements. In-house calibration is performed on a regular basis to ensure quality tools maintain their accuracy.

Case studies

Improving the Production Process

The (6) bends and (8) holes require a detailed and customized fabrication process to match the design print. Hardware insertion and final inspection complete this production process.

Read moreOutdoor Power Equipment Metal Stamping Case Study

Manufacturer of Rotary Lawn Mower Blade Sharpeners and Balancers for the Outdoor Power Equipment Industry

A recommendation from their previous supplier brought Outdoor Power Equipment Manufacturer’s leaders, Gerd & Erik Bauer, to Ultra’s front doors to continue production of their lawn mower blade sharpener.

Read more