Case Study: Delivering Quality with Innovation

Customer

Power Equipment Manufacturer

Part

Breather Cover

Manufacturing Issues

Find a way to pierce the part's four small holes without damaging the progressive stamping die or the actual part.

Meeting increasing quantity demands from year to year.

Customer’s Goals

Minimize the risk of damaging the breather cover and the tooling die during metal stamping.

Deliver the part to match its design print.

Continuously meet production quantities that are predicted to increase from year to year.

Manufacturing Process

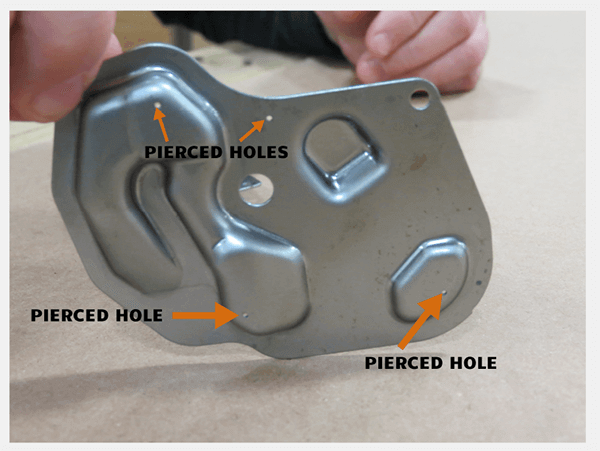

The four small pierced holes labeled in the image are smaller than the actual material thickness. This presents a problem because the continued force of the punch going through the material creates a higher probability of the punch breaking off or becoming off target. And three of these four holes are on non-flat surfaces which also makes the piercing operation more challenging.

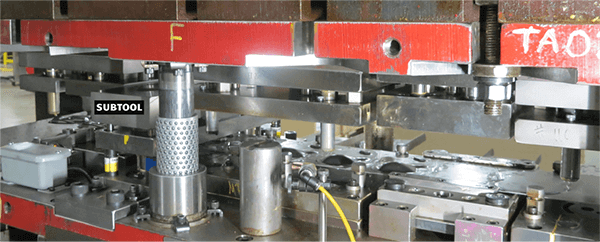

Design and build a subtool for this piercing operation in the progressive stamping die. This design presents two key benefits.

- The subtool in the stamping die keeps the piercing operation separate;

localizing the force of the punch to this specified area. Then the remaining

stations on the tooling die strip aren’t at risk of damage during

production. This also helps keep the entire die strip aligned in the correct

position from operation to operation during production. - This provides our Toolmakers the ability to efficiently remove the

subtool if needed to perform adjustments or repairs in Die Maintenance.

And the subtool can easily be placed back in the correct location on the

progressive stamping die.

After the piercing operation is completed, a bubble of material is created

and then formed to match the other designed features of the breather

cover.

Customer Outcome

Within the first month of production, we were meeting production demands at 2,000 parts per hour without removing the subtool for repairs or adjustments.

The holes of the breather cover are checked with a customized gauge to verify their placement and inside diameters.

Other Case studies

Improving the Production Process

The (6) bends and (8) holes require a detailed and customized fabrication process to match the design print. Hardware insertion and final inspection complete this production process.

Read more →Reducing Costs with a Progressive Stamping Die

Production costs were increasing because a splash guard and (6) drainage slots were added to the part’s design to meet safety requirements. The part’s length changed with these newly added features and made the existing die unusable.

Lower production costs for the fuel filler by utilizing a more efficient production process. Ensure the new features maintain the overall functionality of the fuel filler cup.

Read more →Outdoor Power Equipment Metal Stamping Case Study

Manufacturer of Rotary Lawn Mower Blade Sharpeners and Balancers for the Outdoor Power Equipment Industry

A recommendation from their previous supplier brought Outdoor Power Equipment Manufacturer’s leaders, Gerd & Erik Bauer, to Ultra’s front doors to continue production of their lawn mower blade sharpener.

Read more →Prototyping to Production

A successful transition from a two-piece welded assembly to one-piece aluminum frame with 21 hardware insertions required the manufacturing expertise of our Die Designers and Toolmakers.

Read more →Meeting Design Challenges

The tabs on this lock washer were not forming correctly leading to production delays. Prototyping established a feasible manufacturing process that could metal stamp this part and its tabs to the design print.

Read more →